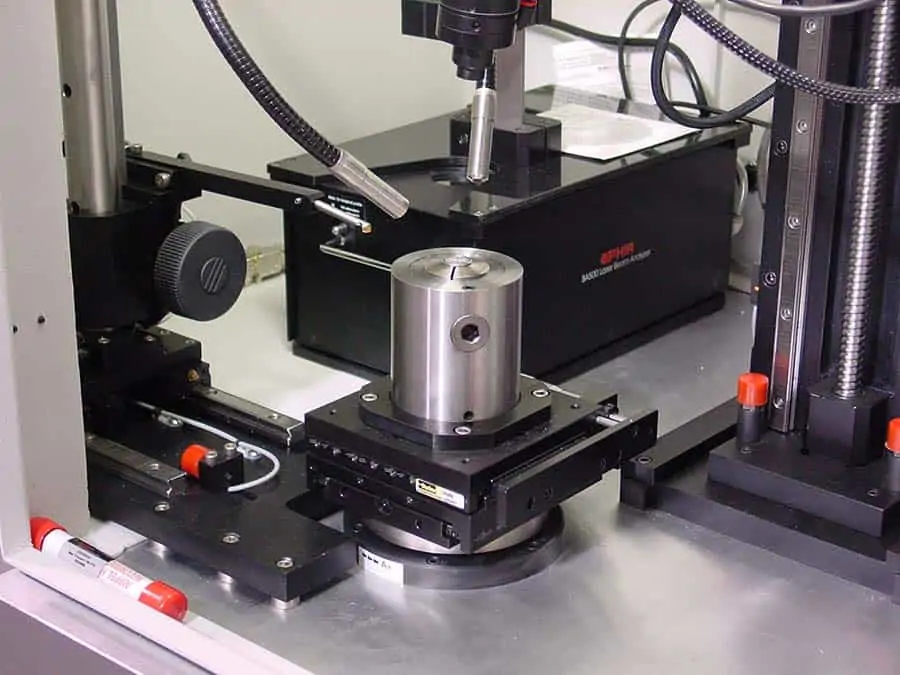

Laser Workstations

Find standard and custom laser workstations for micromachining, laser welding, laser marking, and a multitude of other industrial applications.

Heavy Duty Laser Workstations

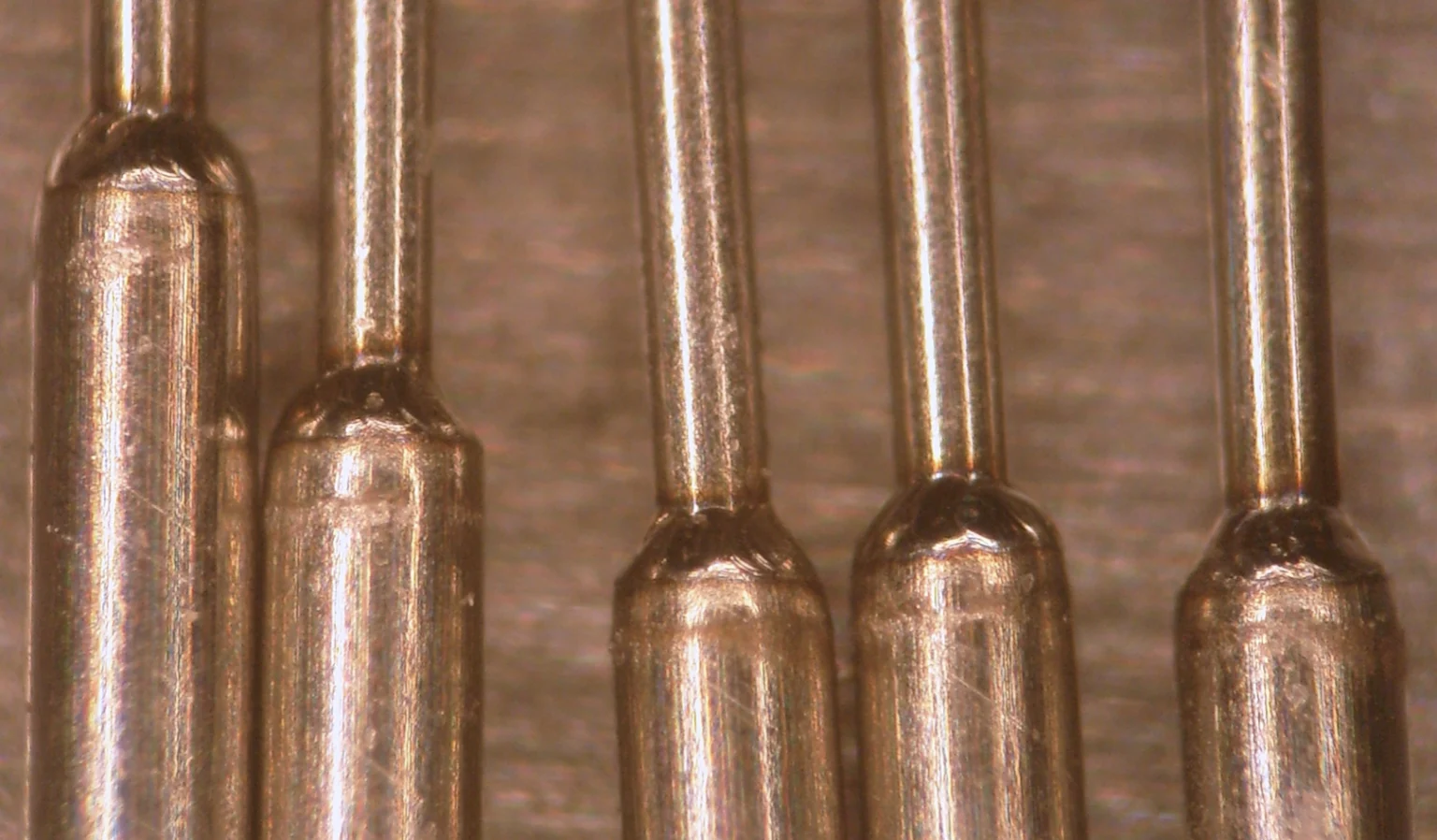

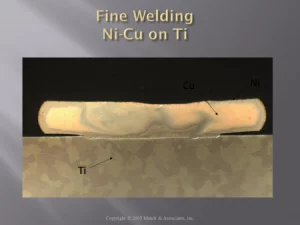

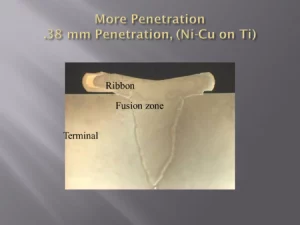

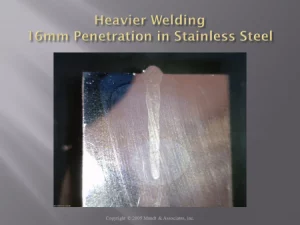

SPD’s principals manufacture superior quality, high precision laser workstations. The workstations combine sturdy machine tools with carefully selected lasers for a wide range of applications. Both standard and custom laser workstations can produce intricate parts and components that are used primarily in high volume production applications but can also be found in R&D Laboratories, working to satisfy the ever-increasing demand for miniaturization of products and components.

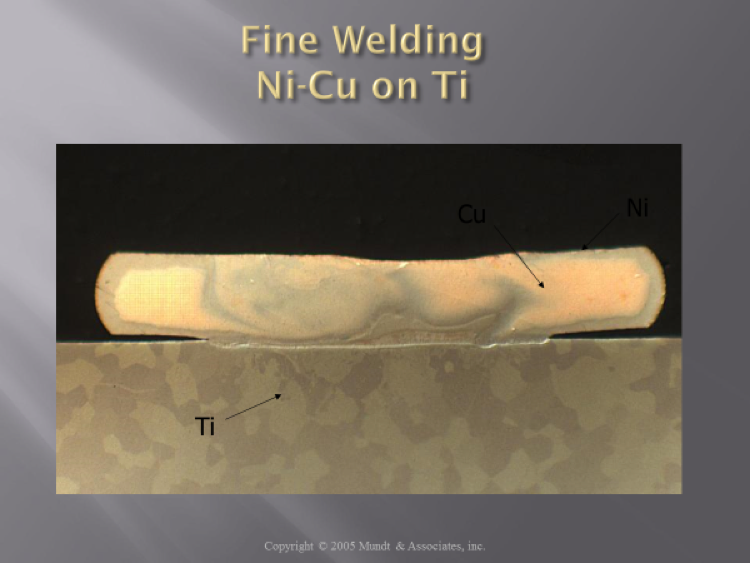

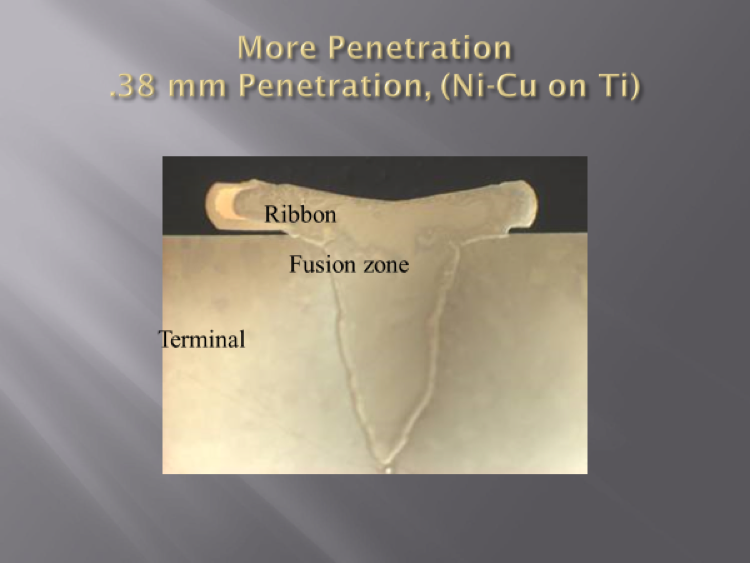

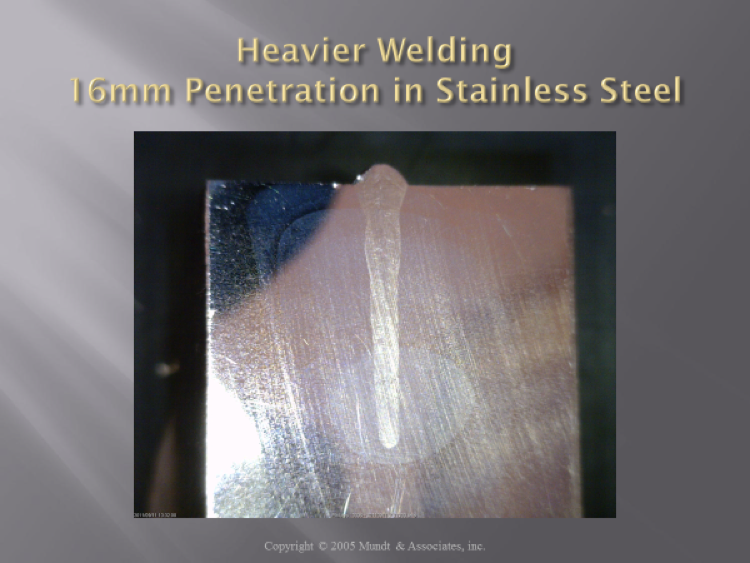

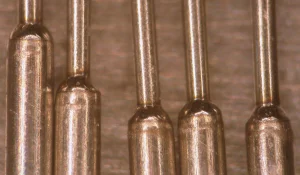

We target manufacturing companies that produce complex precision parts or components made from expensive materials that make scrap elimination a critical element of the production process. Our workstations are used worldwide to produce miniaturized parts for high tech applications, including implantable medical devices, that require complex laser micromachining to produce the miniaturized parts.

Femtosecond Laser Solutions & Support

The SPD focus is to offer solutions and support to give customers a competitive edge.

Regardless of laser type or workstation configuration, our principals have built a reputation for manufacturing rugged precision-built machines designed to operate 24/7 year after year. The workstations are built to produce top quality products that meet the highest quality standards, with emphasis on minimizing waste and downtime.

SPD Principals Workstation Products

Femtosecond Laser Workstation Applications

Send your product drawings or concepts and our technical staff will recommend the best manufacturing process for your application.

We offer free sample processing in our Applications Lab to confirm process feasibility and final product quality. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!