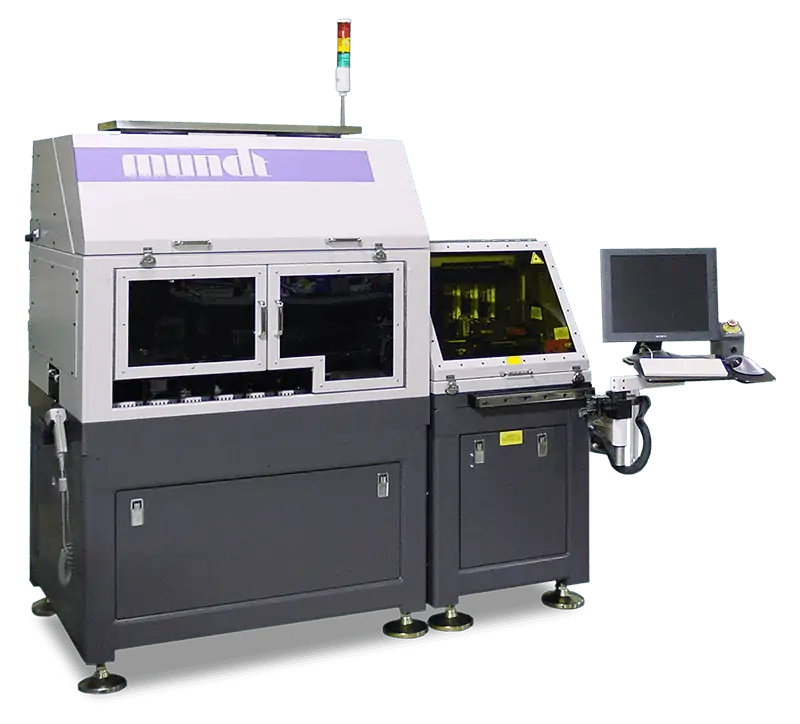

Fully Automated Feedthrough Welder

The Mundt feedthrough welding machine is a fully automated system with two separate machines run by the Mundt fully integrated control system.

The left side is a pick-and-place machine that can handle multiple trays and mixed lots, and the right side is the laser welder. We have many of these machines in production facilities around the world welding feedthroughs into shields for pacemaker cases. Each machine can produce 5 million feedthroughs per year at scrap rates less than 0.5%.

Included among the end products utilizing the automated feedthrough welder are:

- Implantable medical batteries

- Pacemakers

- Defibrillators

- Stent Grafts

- Catheters

- Embolic filters

- Breast implants

- Implantable orthopedic devices

Lean Line Feedthrough Welder

For customers whose feedthrough volume requirements cannot justify investment in the fully automated machine, we offer a Lean Line Feedthrough Welder. With this version, the machine Operator loads the feedthroughs into the shields by hand and places them on an input conveyor. When processing of a part is completed, pneumatic doors on each side of the machine open, the finished part is conveyed out and the next part is conveyed into the machine for processing. Visual inspection of the parts for proper feedthrough placement and weld integrity replaces optical inspection in the automated system.

Please Note

This is a custom-built machine therefore specifications are not provided. If you have a need for a custom solution please contact us with your technical requirements and other data so that we may quote your project.

Send your product drawings or concepts and our technical staff will recommend the best manufacturing process for your application.

We offer free sample processing in our Applications Lab to confirm process feasibility and final product quality. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!