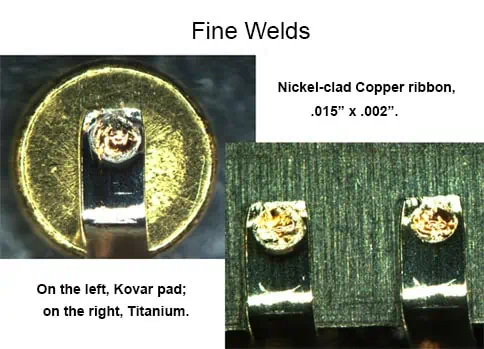

Laser welding has applications in virtually every industry, as it offers numerous benefits including fast welding speeds, short weld cycles, low heat affected zones (HAZ), and minimal distortion. Laser welding is a fast and efficient non-contact method of joining similar or dissimilar materials, requiring access to the weld area from one side only. Since no physical forces are applied in the laser welding process, a much wider range of materials can be joined than with competing welding processes.

Laser welding machines are used extensively in the manufacture of implantable medical devices and components. Medical implants such as pacemakers, defibrillators, and spinal cord stimulators require smooth hermetic welds that are easily achieved with laser welding. Laser welding is the technology of choice for high technology applications where speed, exceptional accuracy, and high reliability are critical requirements.

Laser Micro Welding Transparent Materials

Laser micro-welding enables joining a wide range of transparent materials with transparent and non-transparent materials, like glass-to-glass and glass-to-metal.

No bonding materials are required for laser welding, resulting in reduced costs and increased durability. After material resolidification, strong covalent bonds are formed, providing high stability of the joined parts. Dissimilar glasses can be welded with breaking strengths in the range of the volume of joined materials.

Main features:

- High precision

- Hermetic seals

- Minimum heat-affected zones

- Good mechanical strength

- No extra bonding material required

Do you have a laser welding application or questions about laser welding technology?

Please complete our Contact Us form and we will quickly respond to your request!