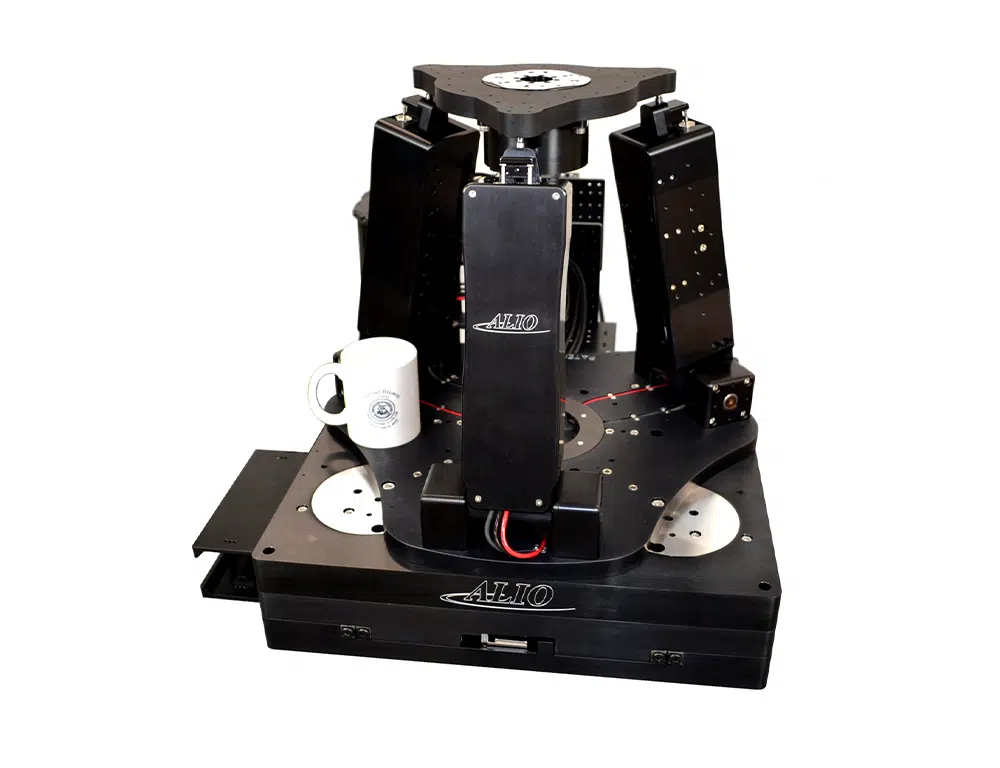

Hybrid Hexapod

ALIO’s patented next generation Hybrid Hexapod® takes a different approach to traditional 6 Degree of Freedom (6-DOF) positioning devices and exhibits much higher performance at extremely competitive prices.

Rather than 6 independent legs (and 12 connection joints) The Hybrid Hexapod® combines a precision XY monolithic stage, tripod and continuous rotation theta-Z axis to provide superior overall performance. This provides traditional Hexapod kinematics obsolete with superior improvements in:

- Precision

- Path Performance

- Speed

- Stiffness & Larger work envelope with virtually unlimited XY Travel &

- Fully Programmable Tool Center Point Locations

The Hybrid Hexapod® has less than 100nm 3-Dimensional 6 axis Point Precision® repeatability

Which makes it an essential technology for mission critical applications in the following:

- Laser Processing

- Optical Inspection

- Photonics

- Semiconductor

- Metrology

- Medical Device Sectors &

- All Micro-Machining Projects

Traditional hexapods cannot achieve sub-micron accuracy because they require the accurate coordination of the movement of all six axes to accomplish a motion profile, even if the requirement is only for a simple single-axes motion. In addition, even though the general perception is that hexapods exhibit good stiffness compared to serial stacked multi-axis systems this is only in the vertical Z axis with weaknesses in the XY plane.

MINI Hybrid Hexapod / Angulares™

The 60-degree tip/tilt travel of the Angulares™ Hybrid Hexapod® is by far the most angular travel range available from any 6-Degree-Of-Freedom (6-DOF) positioner on the market and offers the same unmatched positioning performance found in any of ALIO’s full-line of Hybrid Hexapod systems.

The design makes the Angulares™ capable of unlimited XY travel, Z travel for 62 mm which can be increased to 208 mm using other tripod models, tip/tilt travel of 60 degrees (+/- 30 degrees) with continuous 360-degree Theta-Z, XYZ bidirectional repeatability of less than +/- 0.6 arc-seconds, velocity up to 100 mm/second XY and Z, and less than 10 nanometers linear and 0.1 arc-seconds angular minimum incremental motion.

This model is perfectly suited for applications including

- Aspheric and freeform optical metrology,

- Silicon photonics packaging and probing,

- Laser micro processing (non-planar substrates and taper control),

- Wafer metrology,

- Camera module alignment and assembly,

- Sensor/image stabilization testing and

- Optical element and fiber alignment.

- Precision crossed roller bearing guides,

- Optical incremental or absolute encoder feedback on all axes,

- Linear motor and/or servo ball screw drives,

- Unlimited programmable tool center point locations and coordinate offsets,

- Zero backlash on all axes.

Send us details of your motion control and part positioning requirements.

Our team will quickly evaluate and recommend the best solution to meet your specifications. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!