TRUE NANO® Rotary Motion Systems

ALIO Industries has also developed TRUE NANO® precision rotary stages to meet and exceed today’s demand for high precision rotary motion.

ALIO’S Line of rotary stages continues to expand as the company works with each customer on a one-to-one basis to be able to provide customized motion control solutions rather than off-the-shelf mass motion control products.

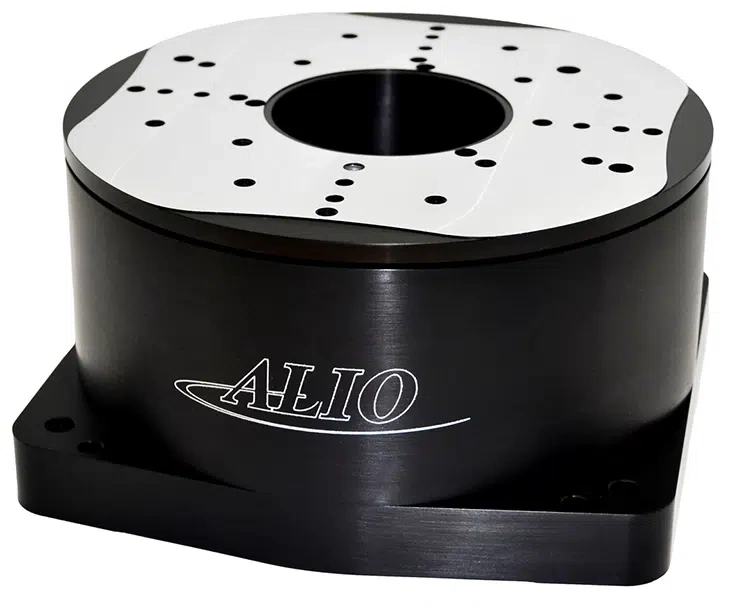

Mechanical Rotary Stages

ALIO’s mechanical bearing rotary stages have been designed with crossed roller bearings for improved stiffness for offset loads and rotational precision. Integrated with servo torque frameless motors, these stages can handle applications where the mass and acceleration needs are extreme, while still maintaining nanometer-level precision performance.

ALIO’s focus on materials and machining is absolute in the manufacture of its rotary product line ensuring the bearings and metal are in ultra-machined parallel surfaces as shown by the machined lands on all stages.

Standard ALIO rotary stages have 0.2 arc-second repeatability using ALIO supplied motion controllers. Standard mechanical crossed roller bearings are rated at 13 to 20 microns of radial and axial run-out, with optional runouts of certain models below 5 microns. The mechanical bearing rotary stage family has multiple motor sizes to meet duty cycles as well as mass and acceleration needs from 80 mm to 300 mm in diameter. Vacuum rotary union options are available on the inner diameter for mounting a vacuum chuck.

Low Angle Mechanical Rotary Stages

ALIO has designed mechanical bearing rotary stages with angular contact bearings representing the most compact design on the market. Integrated with servo ironless motors, these stages best fit metrology applications where small angular adjustment is needed with nanometer-level precision performance.

Air Bearing Rotational Stages

ALIO has designed mechanical bearing rotary stages with angular contact bearings representing the most compact design on the market. Integrated with servo ironless motors, these stages best fit metrology applications where small angular adjustment is needed with nanometer-level precision performance.

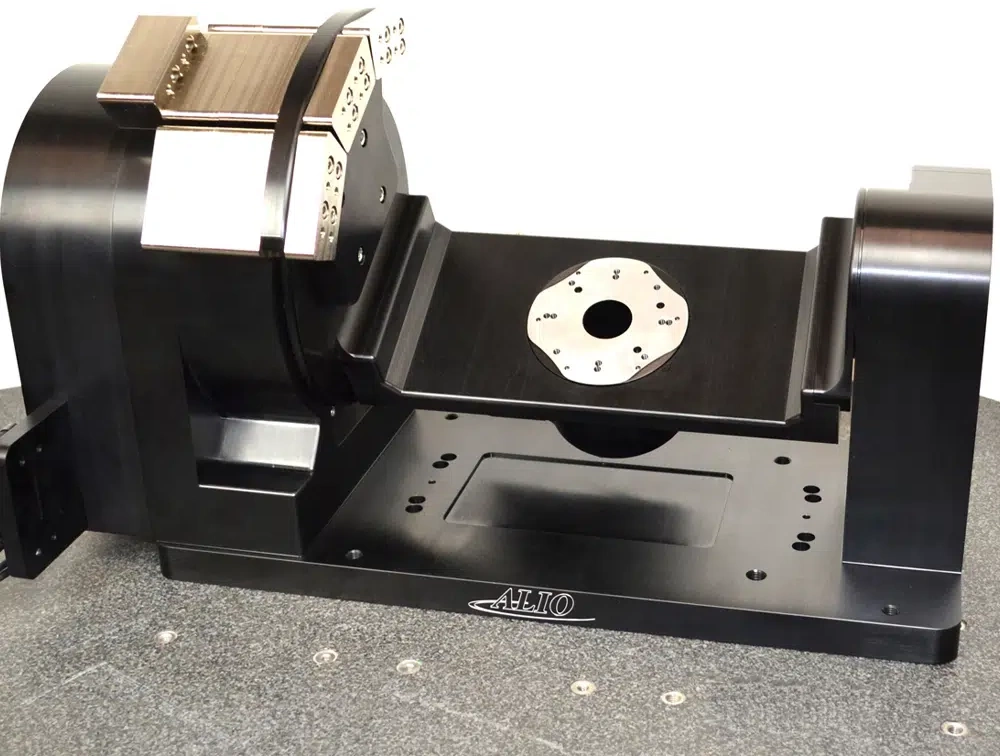

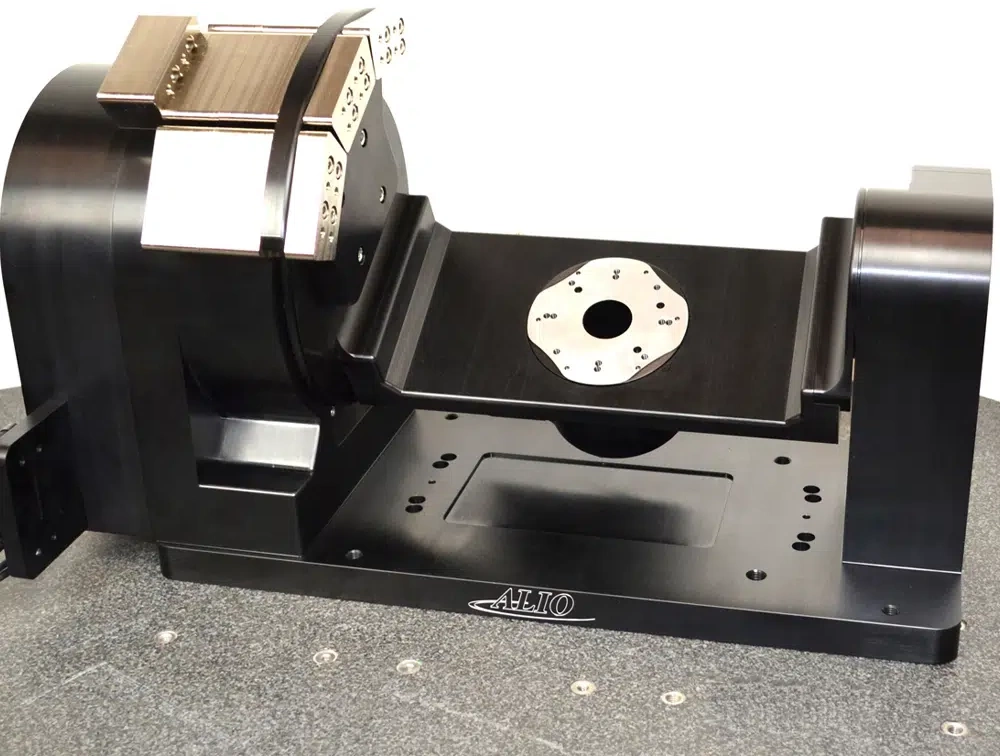

Dual Axis Rotary Systems

ALIO’s two-axis systems are designed around the customers’ mass with variable counterbalance, cable guidance, and cable and air feed-through capabilities. With hard-stops allowing for ± 110 and ± 170 degrees of rotation for nearly unlimited part access on the horizontal axis, ALIO’s dual axis rotary systems exhibit angular travel ± 180 for the rotation about the vertical axis.

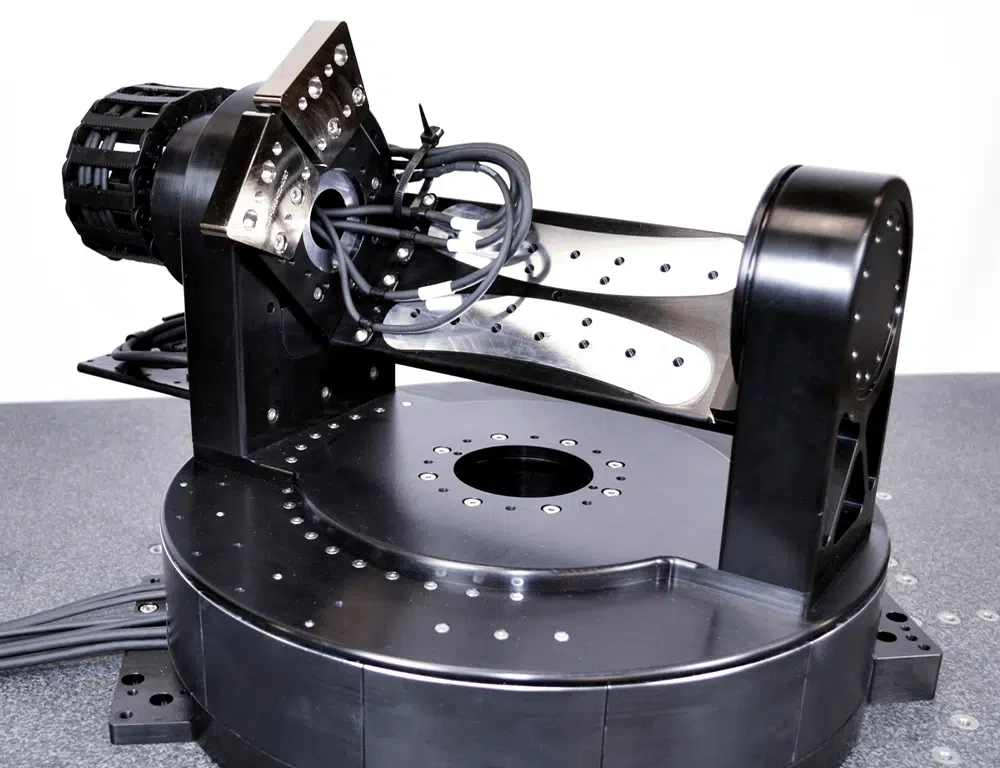

Two-Axis Gimbal

Incorporating ALIO’s industry-leading torque ratings, the company’s two-axis gimbal rotary systems are capable of high rotational speeds while maintaining the stand-out precision levels expected from ALIO Industries’ systems. Metrology, laser processing, additive manufacturing, and many other industry sectors have benefited from these ALIO products., and air purge is incorporated for contaminant protection and longer life. Internal cable and airline routing provide an extremely clean finished product.

AZ-EL Rotary Assembly

ALIO Industry’s AZ-EL rotary assembly systems incorporate the company’s exceptional torque-ratings and are capable of high rotational speeds while maintaining the precision levels synonymous with any ALIO motion control systems. As with the two-axis gimbal system, the AZ-EL rotary assembly systems are used in metrology, laser processing, additive manufacturing, and numerous other industry applications.

Send us details of your motion control and part positioning requirements.

Our team will quickly evaluate and recommend the best solution to meet your specifications. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!