Air Bearing Systems

Leading Edge 6-D Nano Positioning

ALIO Industries has developed leading-edge 6-D Nano Positioning® air bearing motion systems for a wide range of applications in manufacturing, inspection/repair, and metrology. With several patent-pending designs for Planar and Nano®, ALIO’s well positioned for the next generation application demands of TRUE NANO® precision in:

- Photovoltaic,

- Semiconductor

- Ink Jet Deposition

- Lithography &

- Optical Inspection Applications

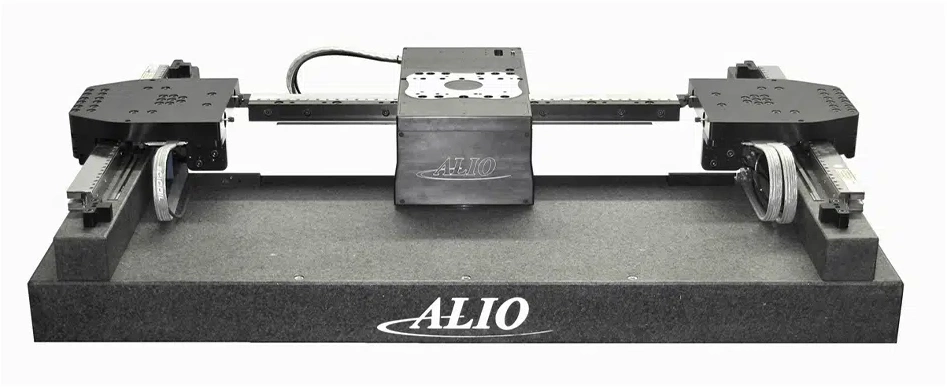

Planar Air Bearing System

ALIO’s patent pending 2 axis planar air bearing system has set the bar in the world of 6-D Nano Positioning®. With 300 mm to over 3 meters of X and Y travel this product family has no equal for True Nano® precision. NIST traceable laser data has measured this product over meters with nanometer precision in all 6 degrees of freedom of a moving member. Expect standard flatness of < 1 µm/meter with less than < 1 arc second of pitch, yaw, and roll. Standard repeatability < 60 nm with optional 10 nm capability in the product family.

Linear Air Bearings

Single axis linear air bearings are available in horizontal or vertical orientation. The linear product family utilizes ironless linear servo motors with variable forces depending on customer needs. These product family standard designs are from 25 mm to 3 meters of travel each with nanometer-level precision.

Patented Nano Z®

Increased demands for True NANO® metrology and processes led ALIO to design and manufacture the NANO Z® patented Z lift air bearing stage to overcome legacy design issues associated with tip and tilt while attaining accuracy of less than 100 nanometers using standard Renishaw Invar encoders. The counterbalanced NANO Z® can easily hold heavy vacuum wafer chucks and still excel with nanometer-level precision over 24 mm of travel.

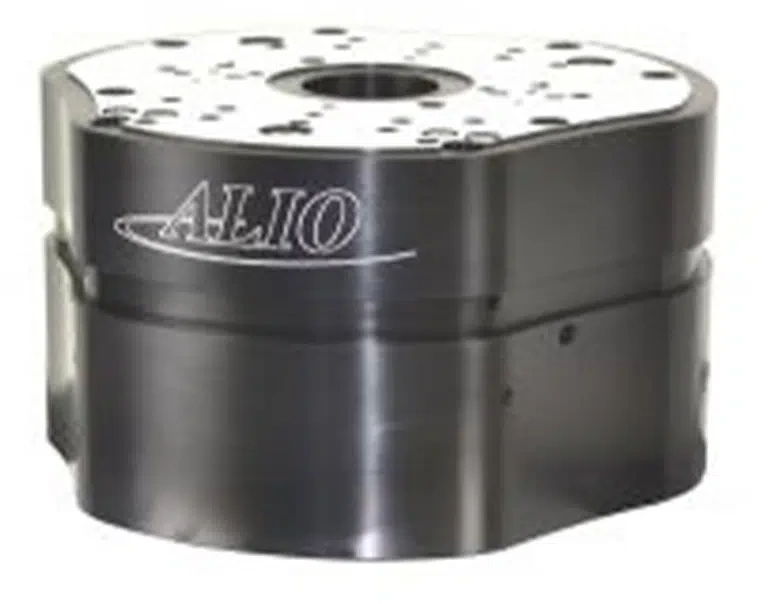

Rotary Air Bearing Stages and Spindles

ALIO’s nano precision rotary air bearing product family ranges from 100 mm and upwards with variable torque options to meet a broad range of applications. This growing product line has excellent axial and radial run-out specifications for extreme precision needs.

Send us details of your motion control and part positioning requirements.

Our team will quickly evaluate and recommend the best solution to meet your specifications. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!