MUNDT IB-1284

Heavy Wire Lead Bonder

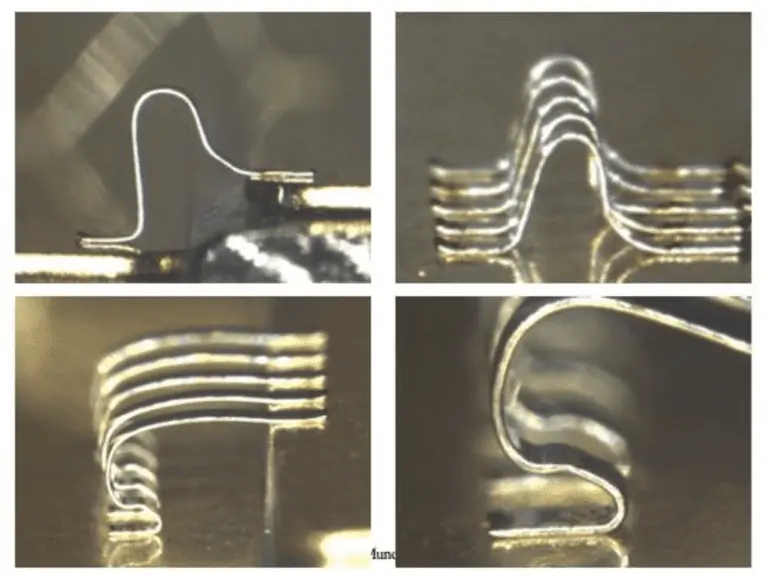

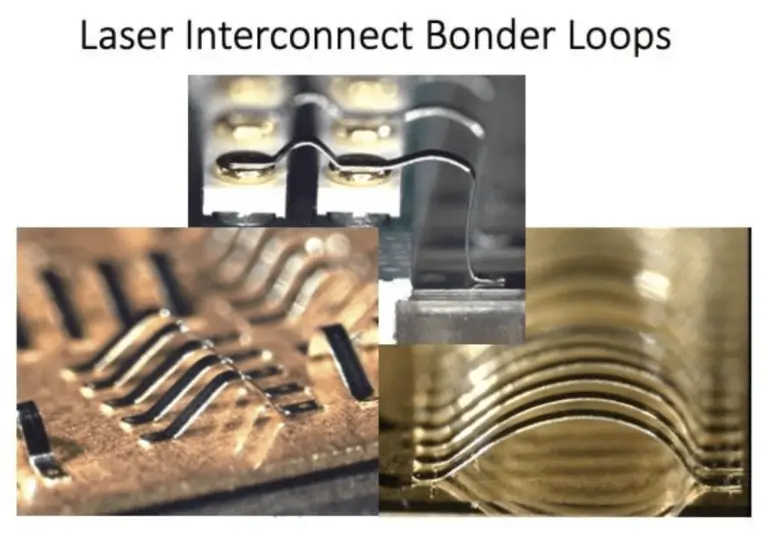

The Mundt Interconnect Bonder employs a novel, patented process for making electrical interconnections. It is a fully automated production system that combines aspects of wire bonding and laser welding.

Features include:

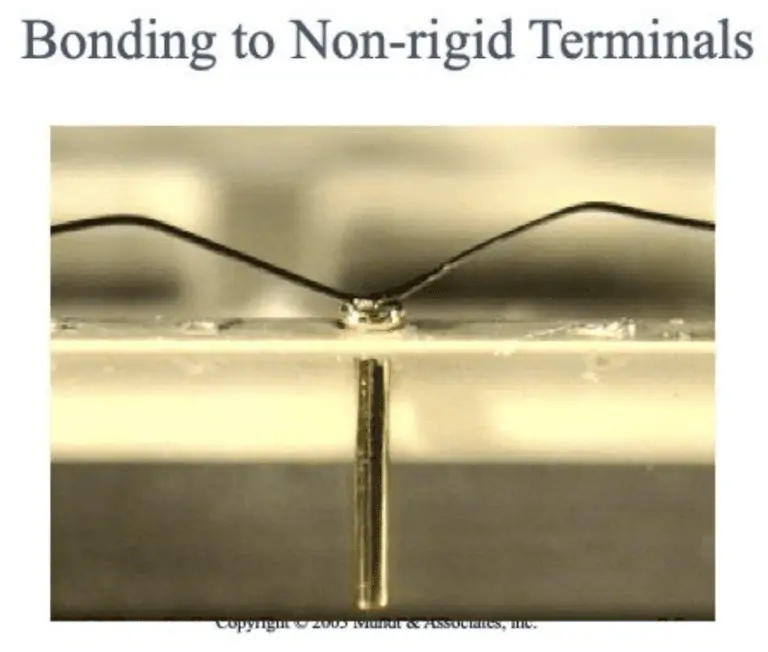

- No ultrasonics – able to bond to less rigid terminals

- Compatible with various ribbon and terminal materials

- High strength connections – typical pull strength for .002” by .015” ribbon is 500-600 gram-force

- Scalable to larger and smaller ribbons.

Ribbon material options include Nickel, Nickel clad Copper, Aluminum, Platinum, Niobium, and Titanium. If a material is weldable and can be formed into ribbon, it is a candidate for this process.

The laser interconnect bonder system was developed for use in electronic assemblies requiring high reliability, long life, and automated assembly. Benefits include less terminal stiffness required, new material options for terminals and ribbons, and excellent fatigue life.

Send your product drawings or concepts and our technical staff will recommend the best manufacturing process for your application.

We offer free sample processing in our Applications Lab to confirm process feasibility and final product quality. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!