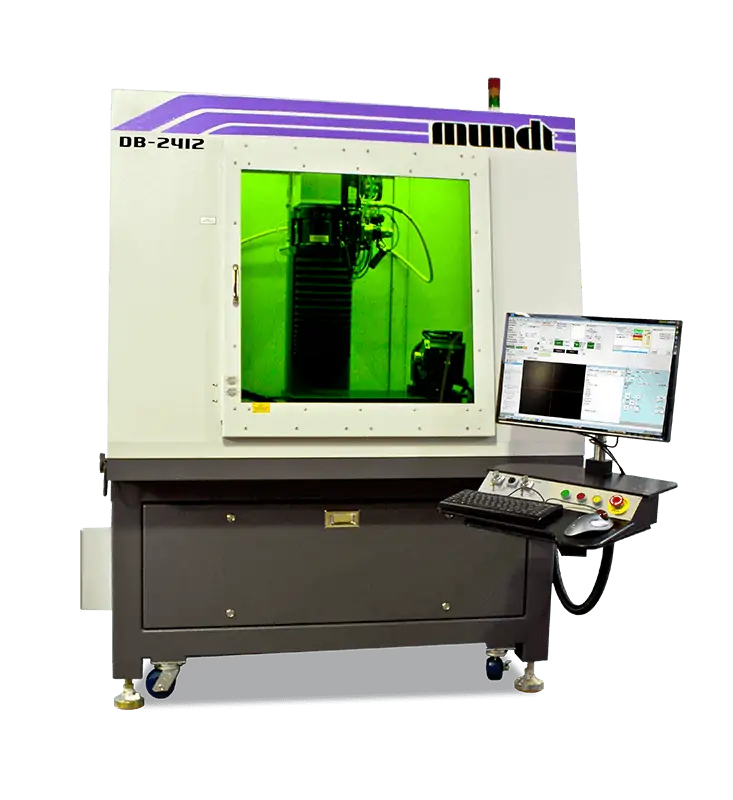

Mundt DB-2412

General Purpose Laser Micromachining Laser Workstation

A General-Purpose Moving Part Laser Workstation

Available in Class I & Class IV configurations

Travel & Work area, 24” X 12” X 18” (also available with 12” travel)

This specialized sturdy machine is built with steel and features the X & Y Axis positioned on the base with the Z Axis mounted on a column. This configuration lends itself for hard optic beam delivery that is utilized with Ultrashort Pulse Lasers.

Multiple Accessories Options are available for the DB Series

Special Feature

This Standard GP-2412 is built to add additional machine options that can be upgraded in the field.

Detailed Specifications

Details

| Brushless Servo Motor Control | X,Y and W |

|---|---|

| Heavy Duty Roller Ways | X,Y and Z |

| Machine Base | 3 in Ground Steel |

| Machine Supports | 4 in Steel Tubing |

| Optional Axes | Up to 12 Axes |

Travel

| X Axis | 24 in |

|---|---|

| Y Axis | 12 in |

| Z Axis | 12 in |

| Tilt Axis Optional | 100 deg |

| Rotary Axis Optional | Continuous |

Maximum Speed

| X Axis | 8 in/sec |

|---|---|

| Y Axis | 8 in/sec |

| Z Axis | 5 in/sec |

| X Axis With Linear Motor | 20 in/sec |

| Y Axis With Linear Motor | 20 in/sec |

| Tilt Axis Optional | 120 deg/sec |

| Rotary Axis Optional Gear Drive | 20 deg/sec |

| Rotary Axis Optional Direct Drive | 1000 rpm |

Accuracy

| X Axis | +/- .0005 in/ft |

|---|---|

| Y Axis | +/- .0005 in/ft |

| Z Axis | +/- .0005 in/ft |

| X Axis Optional Linear Motor | +/- 5 µm/m |

| Y Axis Optional Linear Motor | +/- 5 µm/m |

| Z Axis Optional Linear Motor | +/- 5 µm/m |

| Tilt Axis Optional | 200 arc-sec |

| Rotary Axis Optional Gear Drive | 200 arc-sec |

| Rotary Axis Optional Direct Drive | +/- 10 arc-sec |

Positioning Resolution

| X Axis | .000016 in |

|---|---|

| Y Axis | .000016 in |

| Z Axis | .000016 in |

| X Axis Optional Linear Motor | 250 nm |

| Y Axis Optional Linear Motor | 250 nm |

| Z Axis Optional Linear Scale | 250 nm |

| Tilt Axis Optional | 3.2 arc-sec |

| Rotary Axis Optional Gear Drive | 3.2 arc-sec |

| Rotary Axis Optional Direct Drive | 1.8 arc-sec |

Send your product drawings or concepts and our technical staff will recommend the best manufacturing process for your application.

We offer free sample processing in our Applications Lab to confirm process feasibility and final product quality. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!