FemtoGLASS

An Industrial Workstation for Cutting Glass and Sapphire

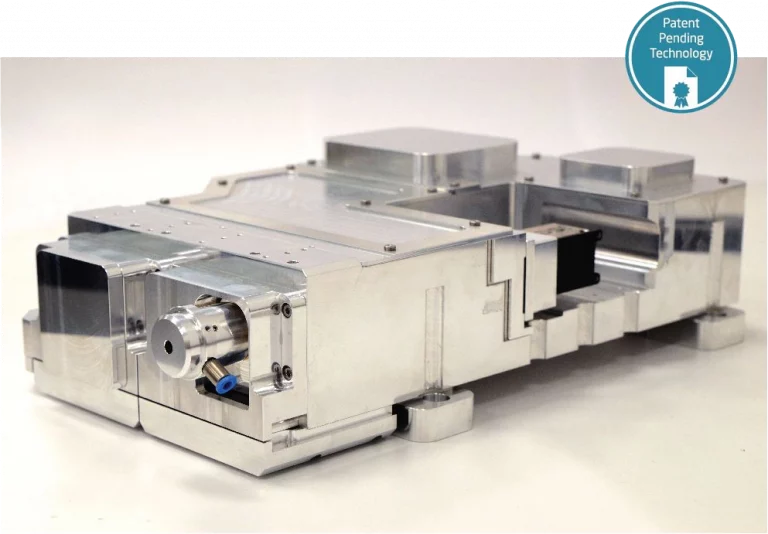

This workstation is based on WOP patented technology for laser cutting Glass and Sapphire. It provides unique ultra-high precision and quality.

Main Features

- Material – Tempered, Non-Tempered Glass & Sapphire

- Irregular Shape Cutting

- High Process Speed up to 1000 mm/s

- Low Chipping < 10 µm for most materials

- Easy Breaking for Non-Tempered Glass & Self-Breaking for Tempered Glass

- Smooth Sidewalls After Breaking, RA < 1µm

- Tested with High DOL Glass from 30 µm to 2 mm Thickness

- DOL Layer from 10 µm to 40 µm

- High Bending Strength

WOP Glass Cutting Workstation OUTPERFORMS other glass cutting methods:

| Blade Dicing | Stealth Laser Dicing | WOP Laser Dicing | |

|---|---|---|---|

| Glass Thickness | 2 – 19 mm | 200 μm – 10mm | 30 μm – 2mm |

| Glass Variety | All types | Non-tempered Sapphire | Tempered Non-tempered Sapphire |

| Cutting Speed | Up to 100 mm/s | Up to 300 mm/s | Up to 1000 mm/s |

| Possible Shapes | Straight cuts only | T-shape and round shape possible | Any shape possible |

| Surface Chipping | <200 μm | <50 μm | <10 μm |

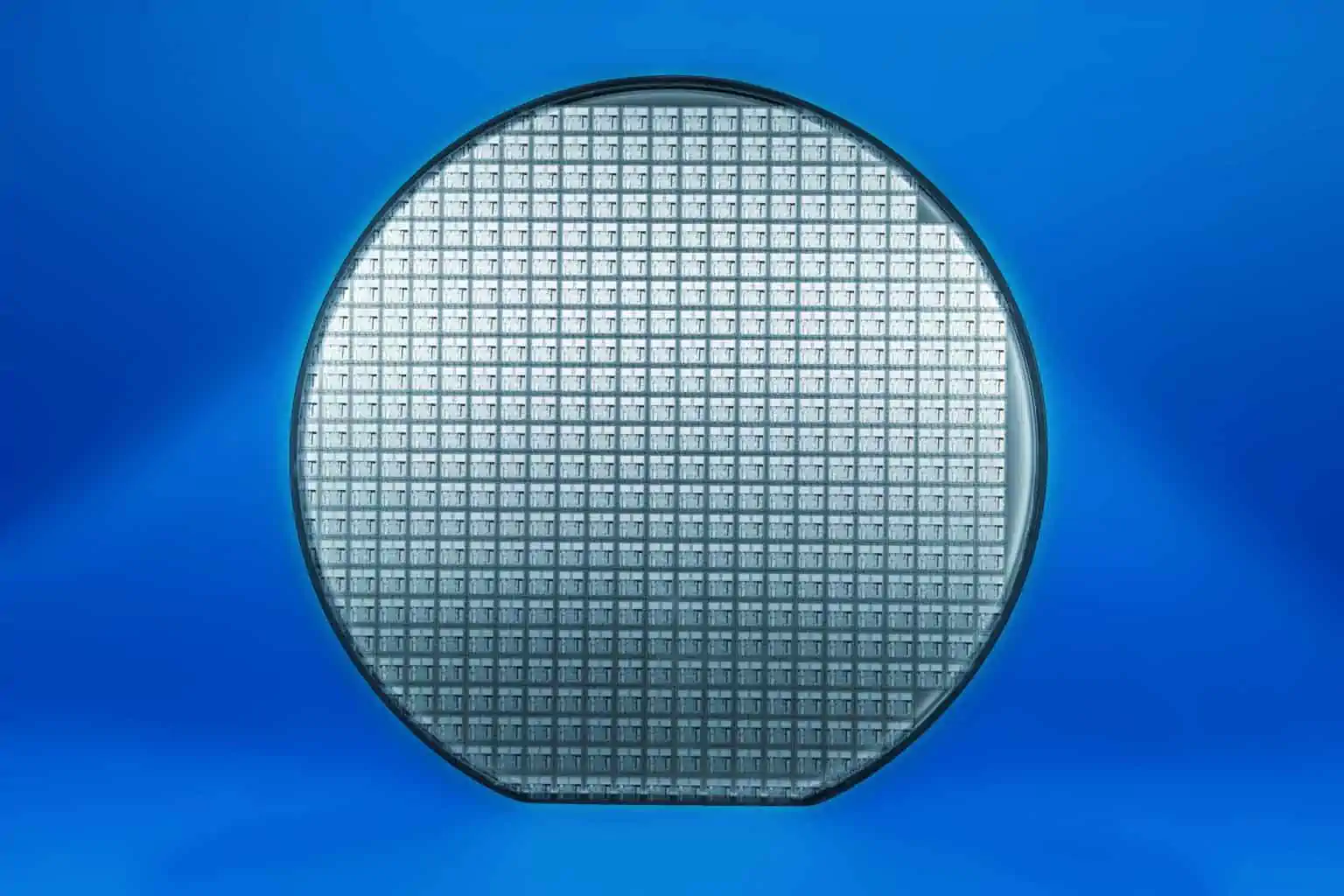

Glass Processing Services

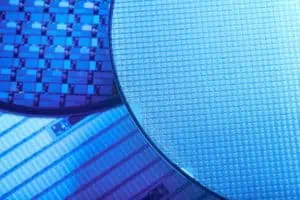

We offer Exceptional Expertise in Glass with Ultra-High Precision & Quality

Glass has widespread uses and is a demanding material. WOP offers over 10 years of experience in glass processing, that includes drilling cutting & dicing, with ultra-high Precision results, small feature sizes & Irregular shape holes.

- A variety of glass types & major suppliers / Corning, Schott, Hoya, AGC

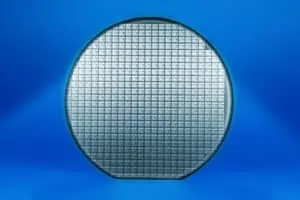

- Wafer size up to 200 mm X 200 mm (8”)

- Wafer thickness from 30 µm to 10 mm

- Circular, square & other-shaped holes

- Straight hole cross section / no taper

- Low Chipping <10µm

- Typical min. hole size 20 µm round

- Positional accuracy +/- 3µm

- No debris on back & front surfaces

- No sagging around holes

- Aspect ratio up to 1:100

- High throughput and yield

- Ability to work with metalized glass types (eg Au, Ni, Cr Mo)

- Minimal or no post-processing is needed

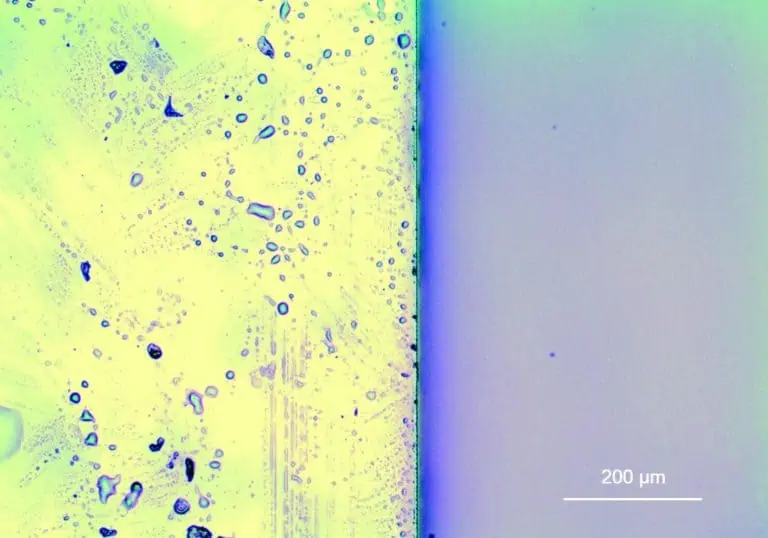

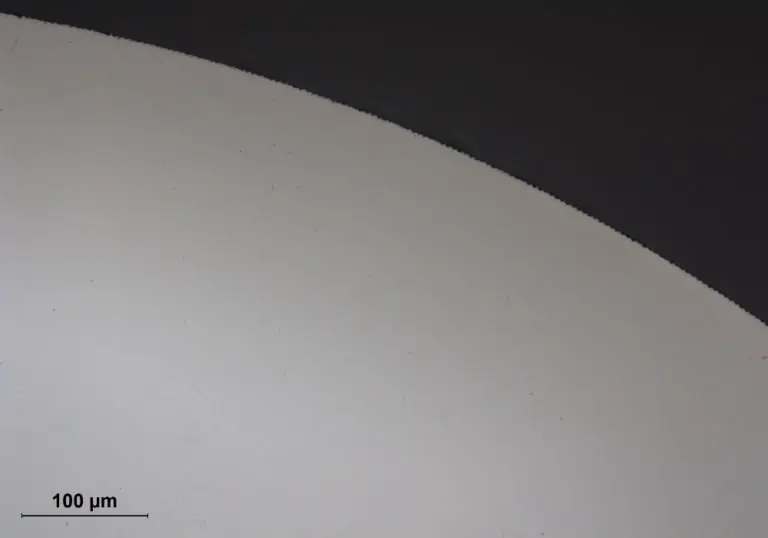

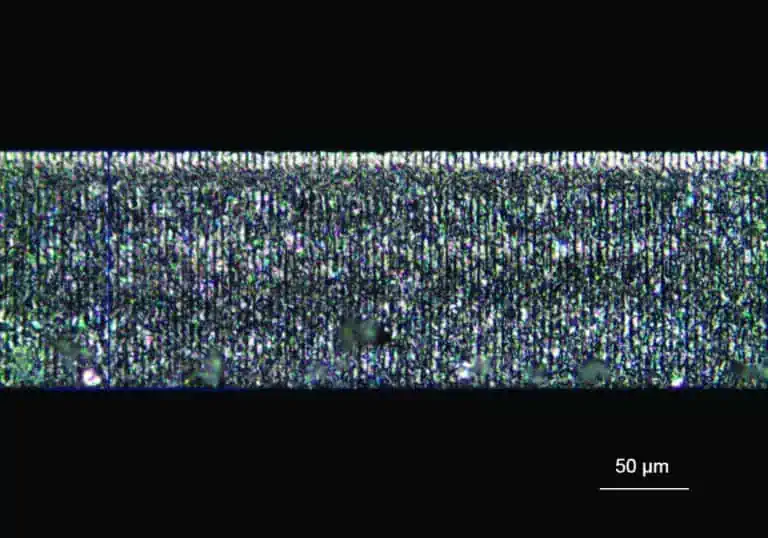

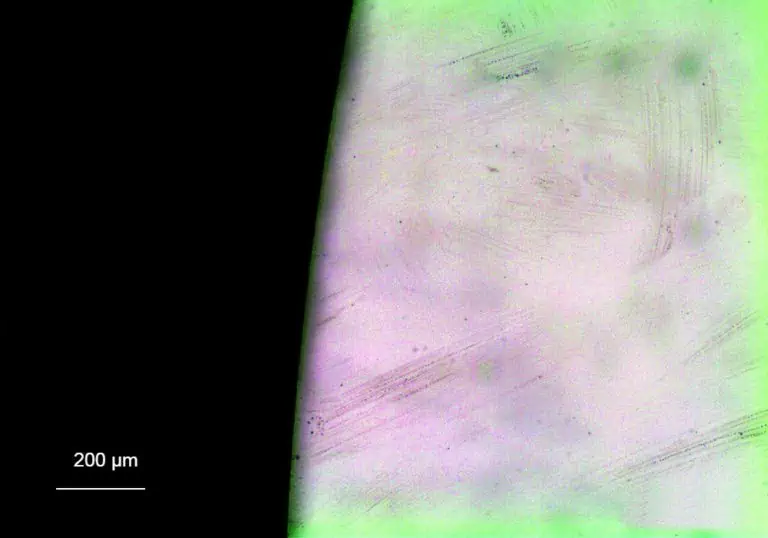

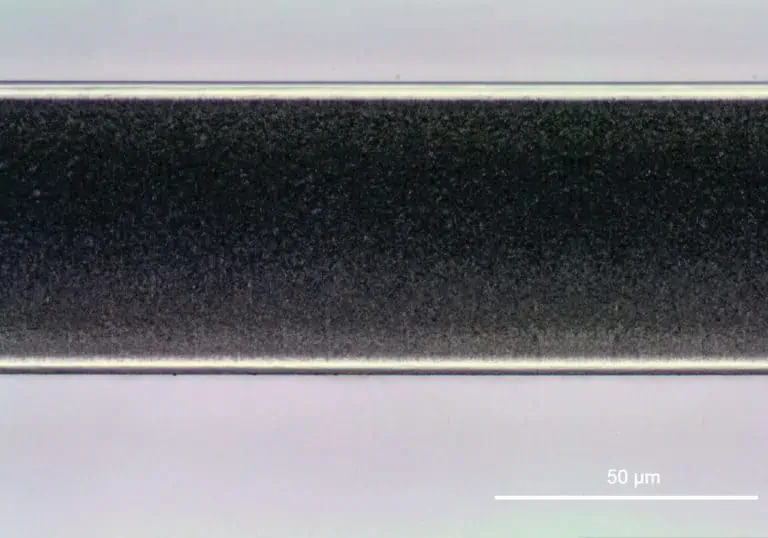

Cut Quality

Cut width less than 1 µm

Low Chipping <10 µm

No post-processing required

Examples of Products Produced with WOP Laser Technology

Features

WOP developed and patented a unique laser technology for ultra-high precision cutting of glass and sapphire. The use of this advanced technology enables production of complex products with ultra-high precision and exceptional quality.

- Suitable materials, tempered & non-tempered glass and sapphire

- Irregular shape cutting

- High process speeds up to 1000 mm/s

- Low chipping <10 µm for most materials

- Easy breaking for non-tempered glass and & self-breaking for tempered glass

- Smooth sidewalls after breaking. Ra < 1 µm

- Tested with high DOL glass from 30 µm to 2 mm thickness

- DOL layer from 10 µm to > 40 µm

- High bending strength

Offers / High Speeds, irregular Shapes, Ultra-high precision results, Thin Glass & Sapphire

- Ultra-fast thin (30µm to 2 mm) glass & sapphire cutting

- High Process speed up to 1000 mm/s

- Irregular shapes

- Inner & outer contours

- Easy breaking for non-tempered glass & self-breaking glass

- High bending strength

- Low chipping, 10 µm

- Smooth side walls after breaking, Ra < 1µm

- Optimized for 1028-1064 nm wavelength (515-532 on request)

- Sealed monolithic housing

- Integrated monitored linear axis with 15 mm travel (Eliminates need for external axis)

- Optional external Machine Vision unit

- Optional alignment module for adjustment

- Packages include optical module & technology license

- Dimensions 395 mm H X 240 mm W X 95 mm D

Exceptional Expertise / Ultra High Precision & Quality

This video demonstrates:

- Glass Spacers

- Micro Drilled Glass

- Glass Carrier Wafers

- Packaging Glass Products

- Glass Probe Cards

- Glass Cutting

Send your product drawings or concepts and our technical staff will recommend the best manufacturing process for your application.

We offer free sample processing in our Applications Lab to confirm process feasibility and final product quality. Upload your part drawing files or sketches on our Contact Us form below.

Please contact us – we are ready to assist!